Innovation

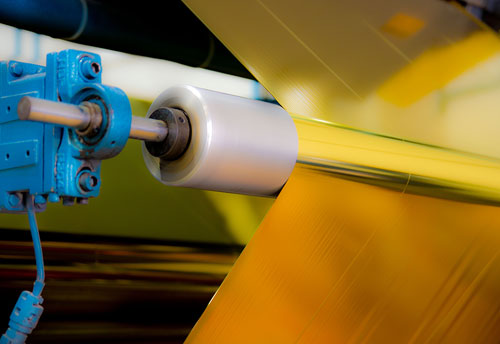

Polyplex's innovation center has adopted a 'lean innovation model' in order to create enduring value for customers. It aims to provide more than a new product or a substrate. Polyplex's innovation center has introduced value-added products in several areas through a well-defined customer engagement process to align innovations with customer requirements. The Company also focuses on developing applications and replacing existing products with alternative solutions.

- Commitment to open innovation: Polyplex leverages the concept of co-creation while working on various innovation programmes with its stakeholders – customers, brand owners, packaging designers, suppliers and adhesive manufacturers. On the basis of this, it classifies customer engagement initiatives as V+ (value plus), W2 (win–win) and P1 (power of one).

- Product and application development programmes: The purpose of this programme is to continuously come up with differentiated products and applications. Innovation in this area is mainly based on developing new functional surfaces and properties besides films addressing the sustainability agenda for PET and PP-based products based on future needs of customers.

The Company offers innovative solutions to its partners. Consequently, Polyplex has successfully adopted the 3R (reduce, reuse and recycle) concept while coming up with new-age packaging substrate solutions. It has taken various initiatives to recycle waste, save energy and use clean technology to reassert its environmental commitment and continually strives to manufacture sustainable products which can gain global acceptance, for example green candy wraps, direct digital printable films, transparent chlorine-free high-barrier films, UV printable carton lamination films, shrink sleeve wraps and label films, etc.

The Company has been consistently introducing specialty products with various innovative applications and uses. Recent examples include films for back sheets of solar panels, thick films for electrical and electronic appliances, easy-to-tear packaging films for food and cosmetics, foldable films for medical and industrial uses, high-barrier high-adhesion films for metallic surfaces, transparent barrier films for food packaging, specialty-coated PET films and films for print media suitable for digital printable and UV inks, among others.

The Company has come up with several projects focusing on CO2 footprint reduction. Digital printing offers high-quality graphics without the usage of solvents unlike conventional printing techniques such as Flexo and Rotogravure. With a lot of technologies available for digital printing itself, Polyplex has been able to develop products for most segments suitable for different digital technologies such as inkjet, dry toner, liquid electro-photography, etc.

Another project focused on sustainability was an attempt to convert general packaging laminate structures from 3 layers to 2 layers, which basically contributes to both source reduction as well as CO2 footprint reduction. With this idea in mind, Company now has a high barrier PE which is successfully being used in shampoo and detergent packaging where it essentially converted a 3 layer structure to 2 layers.

Today, consumers have become highly demanding and are looking for more and more convenience features in packaging formats. “Reclosability”, “Easy to tear” and “Save for later” have become regular concepts in the packaging market.

- "Easy and Straight" tear PET film has facilitated customer convenience through an easy opening of pouches.

- "Twist N Wrap" is one such development which is seen on the market shelves for leading chocolate brands in India. The concept of "Twist N Wrap" is seen as the most innovative and important feature and Polyplex’s innovation has made it possible to bring it to the consumer. Apart from this, the above-mentioned innovation has made possible the conversion from a 3 layer laminate to a 2 layer laminate structure.

- AlOx based transparent barrier lidding films and pasteurization/retort grade films have been commercialized during the year.

- The Company has also come up with specialty coated products for aesthetically pleasing packaging structures. They are targeted to impart a more natural and paper-like look for a soft and subtle appearance.

- The Company is also working actively on the nylon film replacement project with its Thermo-formable grades.

With the current developments around sustainability, Company has commercialized environment friendly alternatives Sarafil PCR PET with more than 100% recyclable content from used PET bottle flakes and other PCR flakes.

The Company has developed various biodegradable films (PET, Blown PP/PE, CPP) which meet the requirements of anaerobic biodegradation either in accelerated land fill or high solids anaerobic conditions complying to ASTM D5511 & D5526 standards.

The Company has come up with monolayer structures for some packaging applications. With polymeric modifications we were able to develop Heat Sealable PET films with high seal strength of up to 2kg/25mm. Such films are instrumental in designing mono polymeric PET laminates for applications like cold seal as well as replacing few multi-layer laminate structures where PET films can be used as sealant layer.

Polyplex has also commercialized various value added products which have generated new business opportunities in Holography, Transfer metallized paper, Offset print applications etc.